A pump is a gadget used to move liquids, for example, fluids, gases or slurries. A pump dislodges a volume by physical or mechanical activity. Pumps fall into three noteworthy gatherings: coordinate lift, dislodging, and gravity pumps. Their names depict the strategy for moving a liquid.

Pumps have two fundamental characterizations;

- Hydrodynamic (or) non-positive removal pumps

- Hydrostatic (or) positive uprooting pumps

Hydrodynamic Pumps

- Conveys liquid starting with one area then onto the next, moderately at low weight (17-21 bar).

- Generally utilized for low weight, high-volume, and stream applications.

- These pumps are not self-preparing, as there is an extraordinary arrangement of leeway between the pivoting and stationary components.

- Cannot make enough vacuum at its gulf, henceforth release rate is low. Examples…

- a) Centrifugal pumps

- b) Axial stream propeller pump.

- These pumps are called non-positive relocation pumps.

Hydrostatic Pumps

- Hydrostatic pumps utilize liquid strain to transmit control.

- These pumps have skintight mating segments and consequently a little measure of spillage could happen.

- These pumps might be either…..

- a) Fixed removal

- b) Variable removal

- These pumps require assurance against overpressure if the protection from stream turns out to be substantial or unbounded, so weight help valve is given.

- It is likewise called as positive dislodging pumps.

There are mainly three types of hydrostatic pumps gear pumps, vane pumps, piston pumps

Outer Gear Pump

Application

Regular outside gear pump applications incorporate, however are not restricted to:

- Various fuel oils and lube oils

- Chemical added substance and polymer metering

- Chemical blending and mixing (twofold pump)

- Industrial and versatile water driven applications (log splitters, lifts, and so forth.)

- Acids and scathing (tempered steel or composite development)

- Low volume exchange or application

Inside Gear Pump

Application

Regular inner gear pump applications incorporate, yet are not constrained to:

- All assortments of fuel oil and lube oil

- Resins and Polymers

- Alcohols and solvents

- Asphalt, Bitumen, and Tar

- Polyurethane froth (Isocyanate and polyol)

- Food items, for example, corn syrup, chocolate, and nutty spread

- Paint, inks, and shades

- Soaps and surfactants

- Glycol

Flap Pump

Application

Normal revolving projection pump applications incorporate, yet are not constrained to:

- Polymers

- Paper coatings

- Soaps and surfactants

- Paints and colors

- Rubber and glues

- Pharmaceuticals

- Food applications

Gerotor Pump

The gerotor pumps have trochoid gears. Smooth task, low commotion and brilliant suction qualities are for the most part recognizing highlights. The halfway situated drive gear drives an outer unpredictably situated annular gear. Because of which holes inside the pump pack and develop, in this manner making the suction and feed productivity.

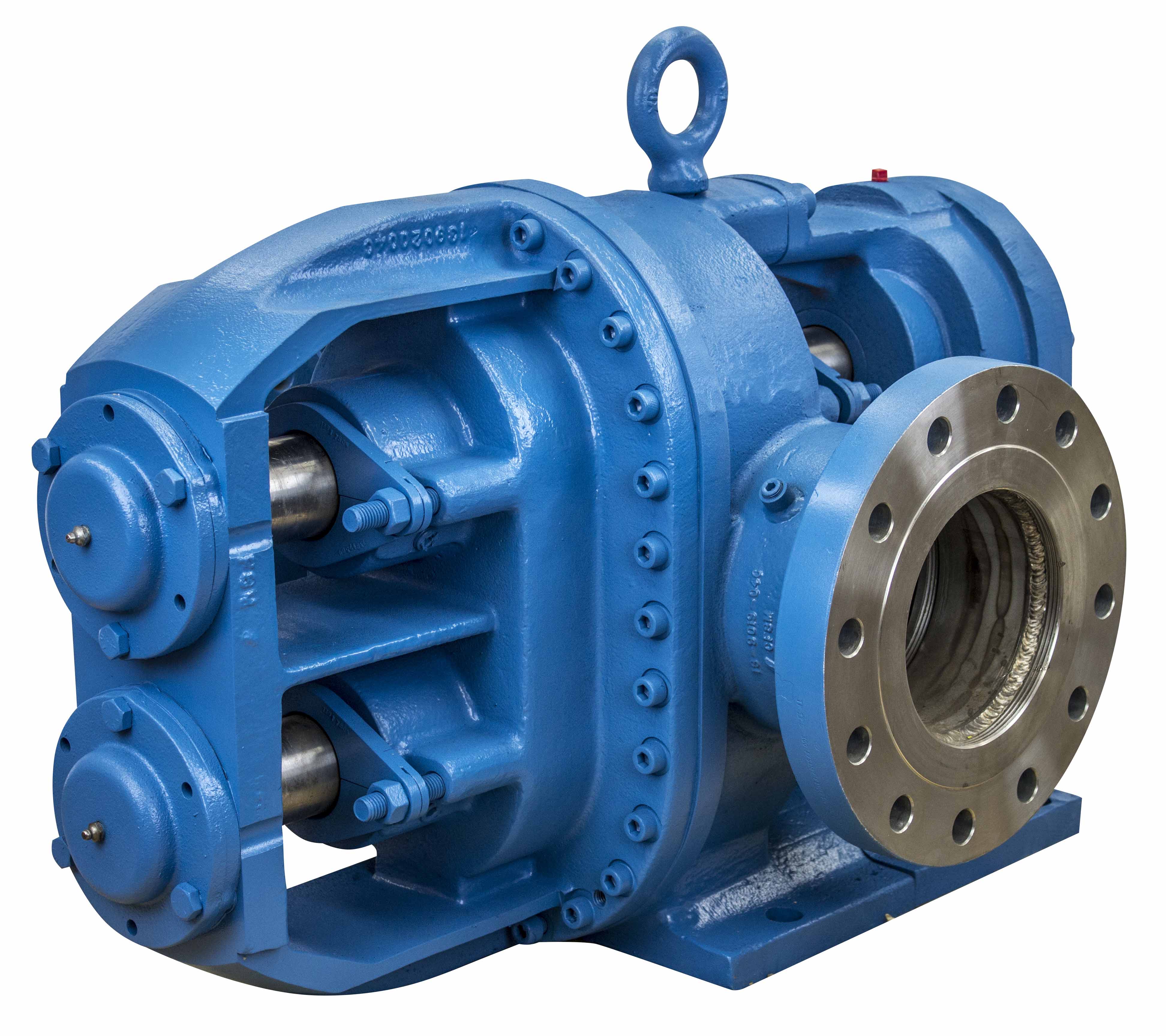

Screw Pump

A screw pump is a kind of turning pump which is furnished with screws that work together and pivot inside a tube-shaped pit or liner. The liquid enters from the suction side of the pump and moves directly along these intermeshing screws to the release side of the pump. The clearances between the screws and the liner are little thus the liquid additions weight while traveling through the pump.

Uses of PD Pumps

PD pumps are found in an extensive variety of utilization

- chemical-preparing

- liquid conveyance

- marine

- biotechnology

- pharmaceutical

- As well as sustenance, dairy, and refreshment handling.

- Their adaptability and ubiquity is expected to a limited extent to their moderately conservative plan, high-consistency execution, ceaseless stream paying little heed to differential weight, and capacity to deal with high differential weight.

Vane Pumps

Application

- Aerosol and Propellants

- Aviation Service – Fuel Transfer, Deicing

- Auto Industry – Fuels, Lubes,

- Refrigeration Coolants

- Bulk Transfer of LPG and NH3

- LPG Cylinder Filling

- Alcohols

- Refrigeration – Frons, Ammonia

- Solvents

- Aqueous arrangements

Pivotal Piston Pump

Pivotal cylinder pumps have a few cylinders that are orchestrated parallel to the drive shaft. They are accessible as either factor pumps or consistent pumps. Variable removal hub cylinder pumps work as indicated by the twisted pivot guideline. They modify the geometric yield volume from most extreme to zero. Therefore, they differ the stream rate that is given to the heaps.

Settled removal hub cylinder pumps work as indicated by the twisted pivot guideline. They have a consistent yield volume and in this manner convey a steady stream rate at a particular pivot speed.

Spiral Piston Pump

Spiral cylinder pumps are utilized as a part of uses that include high weights (working weights over 400 bar and up to 700 bar, for example, squeezes, and machines for handling plastic and machine apparatuses that brace power through pressure. Spiral cylinder pumps are the main pumps equipped for working acceptably at such high weights, even under nonstop task.

Spiral cylinder pumps are accessible in two distinct designs. With unpredictable barrel hinder, the cylinder pivots inside the inflexible outer ring. Unpredictability decides the stroke of the cylinders. Or then again, with a capricious shaft, the turning unusual shaft causes radially-swaying cylinder developments to be delivered. Most models have an odd number of cylinders to lessen the stream throb.

Centrifugal PUMP

A Centrifugal Pumps a mechanical gadget intended to move a liquid by methods for the exchange of rotational vitality from at least one driven rotors, called impellers. Liquid enters the quickly turning impeller along its hub and is thrown out by outward power along its boundary through the impeller’s vane tips. The activity of the impeller expands the liquid’s speed and weight and furthermore guides it towards the pump outlet. The pump packaging is exceptionally intended to choke the liquid from the pump gulf, guide it into the impeller and afterward moderate and control the liquid before release. Now ebara centrifugal pumps are also available.

Submersible pump

Controlling consistent and bother free directing administrations to farming, city, business and modern divisions, Submersible Pumps with the expect to decrease water lack issues in remote territories. The tough cast press enameled bowls alongside tempered steel impellers make a solid and viable blend.

Execution OF pump

- Pumps are typically appraised by their volumetric yield what’s more, weight.

- Volumetric yield (conveyance rate or limit) is the measure of the fluid that a pump can convey at its outlet port per unit of time at a given drive speed, generally communicated in GPM or cubic inches every moment.

- Pumps are at times evaluated by removal that is the measure of fluid that they can convey per cycle or cubic inches per upheaval.

- As weight increments, volumetric yield diminishes.

- This drop in yield is caused by an expansion in interior spillage (slippage) from a pump’s outlet side to its channel side

- Slippage is a measure of a pump’s effectiveness and normally is communicated in percent.